Forum Highlights

Why Join This Forum

10 REASONS WHY YOU SHOULD ATTEND

- Be part of the exclusive gathering of business leaders, innovators, entrepreneurs, CEOs, investors and thinkers for meaningful exchanges to catalyze innovations in food safety, traceability and processing technology

- Stay ahead of the technology curve and discover what’s truly cutting-edge in food safety to future-proof your food manufacturing processes

- Embrace new food safety, traceability and processing technologies intelligently to enhance efficiency, effectiveness and profitability

- Acquire actionable insights, proven solutions and effective strategies to accelerate your food safety, traceability and processing initiatives

- Engage and network with some of most innovative minds at the forefront of the food safety, traceability and processing community to build valuable partnerships

- Exclusive international and local case studies shared by prominent speakers who have played imperative roles in realizing innovations in food safety, traceability and processing technology

- 360-degree approach: Evaluate food safety, traceability and processing initiatives holistically in areas like policies, infrastructure planning, environmental sustainability, IoT, automation, AI, data and food security

- Invaluable takeaways from best practices, market-leading and award-winning case studies, and practical insights on how innovations in food safety, traceability and processing technology can be implemented in a cost-effective manner to bring about safer food and greater efficiency

- Interactive, outcome-focused “How To” roundtable discussions, panels, fireside chats to get all pressing questions answered, and assist delegates to successfully map out a transformational food safety, traceability and processing journey for various category-specific food types

- An exclusive platform for industry experts to address food safety, traceability and processing challenges, share integrated technological solutions and forge new valuable partnerships

Hot Topics to be Discussed

- SPC Ardmona Case Study: Innovations in Food Safety

- How Serialization Counters Food Fraud at Pernod Ricard

- Blockchain: Increasing Food Provenance and Transparency

- Countering Food Fraud with Blockchain

- Coles Case Study: Real-time Tracking and Monitoring of Food Supply Chain with IoTs

- Invisible Tracking Technology to Combat Food Fraud

- Raising Food Safety Levels with X-ray Contaminant Detection

- Kraft Heinz Case Study: Continuous Improvement in Food Safety & Quality

- Fonterra Case Study: Creating Food Safety Culture

- Coca Cola Amatil Food Safety & Processing Case Study

- Compliance with New “Country of Origin” Labeling

- Improving Food Safety Pathogen Detection with Next-Generation Sequencing (NGS)

- Improving Food Safety and Shelf Life with Smart, Active and Antimicrobial Packaging

- How Artificial Intelligence Improves Food Processing, Safety and Compliance

Pre-Forum Activities

21 January 2019

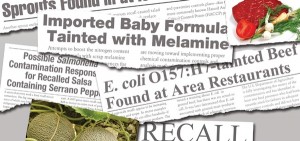

FOOD RECALLS AND CRISIS MANAGEMENT WORKSHOP BY THE RECALL INSTITUTE

A series of product recall crises in the Australian food industry recently has significantly influenced consumers’ perception of food safety. The underlying concern is whether dwindling consumer confidence will spill over to other Australian food products. Earlier this year, a listeria outbreak linked to rockmelons claimed the lives of 6 people. This incident caused a 90% drop in rockmelon sales across Australia, leaving consumers deeply concerned about the safety of rockmelons. The next product recall crisis could trigger call for increased regulation that regulators would have to respond. Two key concerns stemming from food recalls are loss in sales and loss in brand reputation. This workshop will address any food recall challenges and equip delegates with powerful brand reputation protection strategies.

Steven Hather

Director

The Recall Institute

![]()

FOOD SAFETY INNOVATIONS SITE TOUR AT THE UNIVERSITY OF MELBOURNE

Food companies around the world are increasingly concerned about the implications of foodborne outbreaks and rising concern on food fraud and safety standards. This gives rise to a stronger demand for traceability from suppliers and new measures to improve overall food safety standards. This site tour will show you the latest innovations in food safety, processing and traceability. Discover Biometrics and Sensory Analytic at University of Melbourne, the first in Australia. Combining invasive & non-invasive method, measurement of the sub-conscience dimension for preference of Food & Beverages become possible with Biometrics and Sensory Analytic.

FOOD SAFETY INNOVATIONS SITE TOUR AT INSPECTION SYSTEMS

As the demand for food safety standards grows, X-ray detection is growing alongside it as the ideal gatekeeper. Spotting contaminants in food before it leaves the factory holds enormous potential to prevent foodborne outbreaks, mass recalls and other disasters. Join us for a tour of one of Australia’s leaders in food screening technology, Inspection Systems, where you will witness a demonstration of the latest X-ray detectors. You will also learn how near-infrared fat, moisture and protein measurement, as well as non-invasive temperature measurement, further help food producers ensure food safety and compliance with associated regulations.