|

The rise of smart manufacturing and industry 4.0 technologies

With pro-business policies, competitive taxes, a robust intellectual property regime, and an educated, reliable, adaptable workforce, Singapore is uniquely positioned to leverage on Industry 4.0 and smart manufacturing to drive unprecedented economic growth. As Singapore’s manufacturing sector continues to face unprecedented challenges amid global economic headwinds, the time is ripe for a holistic revamp of its manufacturing sector to reap the full benefits of Industry 4.0, while proactively managing the challenges and dislocations created by this historic transition.

The first day of the forum will kick start with sessions exploring the current Industry 4.0 initiatives driven by the Singapore manufacturing sector and providing a better understanding of the current local, regional and global landscape. The subsequent sessions will dwell on the massive benefits of Additive Manufacturing, Augmented and Virtual Reality and Artificial Intelligence. Case studies of local and global organizations who have successfully implemented smart manufacturing strategies to transform their manufacturing processes will also be showcased and discussed in great details. These will inspire delegates to push past the status quo and envision future transformative roadmaps towards Industry 4.0.

At the end of day one, the forum features a panel discussion, which will examine how SMEs, which contribute to 99% of Singapore’s total 216,900 enterprise count. Through this panel discussion, delegates will be able to envision how SMEs can take advantage of advanced manufacturing and the assistance and solutions available to aid in their transformation.

|

| TIME |

AGENDA |

|

| 09:00 |

Opening Address and Day 1 Highlights by Chairperson |

|

|

Bob Gill

General Manager Southeast Asia

ARC Advisory Group

|

|

| 09:15 |

Visionary Keynote: Singapore’s Advanced Manufacturing Initiatives “Industry 4.0” – Transforming the City-State into Asia’s Future Manufacturing Powerhouse

- How digital transformation can help Singapore’s manufacturing sector handle pressure from both regional competition and domestic restructuring

- Smart Manufacturing as a key driver for Singapore’s growth towards an innovation-driven economy

- Singapore’s i4.0 strategy to move the industry towards quicker adoption and help manufacturers transition from a value-add model to a value creation model

|

|

|

Brandon Lee Kok Hoh

Chairman, Smart Automation Industry Group

Singapore Manufacturing Federation

|

|

| 09:45 |

Smart Factory of the Future Case Study: Infineon transforms its Singapore Plant into a Smart Factory

- Smart Enterprise program: Embracing horizontal, vertical and digital integration

- Embracing digitalization: building the foundation and starting pioneer initiatives

- Becoming smarter: Incorporating advanced manufacturing elements like robotics, automation, real-time global production network and end-to-end digital integration

|

|

|

Roxane Desmicht

Senior Director Corporate Supply Chain

Infineon Technologies |

|

| 10:15 |

Morning Refreshments & Networking Session |

|

| 10:30 |

International Roundtable Discussions: Smart Manufacturing and Industry 4.0 Technology Success Stories and Takeaway Lessons from Key Players in the Region

|

|

|

Liu Qiao

Executive Director & Chief Technical Officer

3M Japan |

|

|

|

|

|

Jay Jason Gan

Director, Strategic Supply Chain Management

Flextronics |

|

|

|

|

|

Dennise Tanoko Ardi

Team Lead

A*STAR

|

|

|

|

|

|

Christian Tiemann

Director Factory Integration

Infineon Technologies |

|

|

|

|

| 11:30 |

Rolls Royce Smart Manufacturing Program: Creating Tomorrow’s Technological Solutions

- Rolls Royce’s Smart Manufacturing journey thus far: A glimpse of the manufacturing giant’s efforts with Industrie 4.0 today

- Harnessing collaborations for the next massive technological transformation

- How Rolls Royce and its partners are developing next-generation aerospace manufacturing, maintenance, repair and overhaul capabilities enabled by advanced processes, automation and digital technologies

|

|

|

Luc Scheffer

Smart Manufacturing Programme Manager

Rolls Royce |

|

| 12:00 |

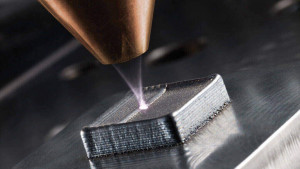

The Current Positioning of Metal Additive Manufacturing & a Look at the Current State of the Industry

- How metal additive manufacturing enables the next revolution for manufacturing

- The possibility to produce complex parts without the design constraints of traditional manufacturing routes

- Unrivalled design freedom with the ability to manufacture parts from a wide range of materials

|

|

|

Alexander Liu

Head, Digital Fabrication and Additive Manufacturing Centre, School of Engineering

Temasek Polytechnic |

|

| 12:30 |

Lunch & Networking Session |

|

| 13:30 |

The Frontiers of Digital Design and Manufacturing: How the New Era of Manufacturing Will Be Enabled by Highly-Integrated Digital Advances

- 4D printing and the world of novel, smart and high performance materials

- Computer-aided design system to enable designers to take advantage of the unique capabilities of additive and digital manufacturing

- Simultaneously enabling the design of the product, its materials, and their manufacturing processes

|

|

|

Low Hong Yee

Centre Director – Digital Manufacturing and Design Centre

SUTD |

|

| 14:00 |

Incorporating Industry 4.0 into Your Organization’s Strategy: Gaining Organization-wide Buy-in

- Obtaining broad consensus of the advantages to validate the move to industry 4.0

- Changing the long-standing culture and moving from automation and control towards true cloud-based services and interoperability

- Leadership 4.0: The importance of having your top management on board to embrace digital transformation

- Learning lessons, challenges and the next step forward

|

|

|

Peter Toh

Senior Programme Manager

Fong’s Engineering & Manufacturing |

|

| 14:30 |

The Need for Intelligent Warehouses to Spearhead Singapore’s Growing Digital Economy

- How digitization is picking up pace in Singapore’s warehouse aisles and factory floors

- Why businesses need to smarten up the facilities with AI, robotics and IIoT and raise the operating effectiveness of operations through cyber-physical collaborations

- Harnessing the power of technology to not only optimize existing processes but also expand business opportunities

|

|

|

Koh Niak Wu

CEO

The Intelligent Warehouse |

|

| 15:00 |

Data-driven Smart Manufacturing: How Data Empower Decisions on The Shop Floor

- Data insights from IIoT and digitization to drive production floor improvements and quality

- Maximizing the value of data through analytics from real-time notifications to statistical process control for immediate gains

- Predictive maintenance with connectivity and data collection to enhance customer experience and enhance loyalty

|

|

|

Willson Deng

Chairman

Smart Manufacturing Consortium |

|

| 15:30 |

Afternoon Refreshments

|

|

| 15:45 |

3M Case Study: Innovation by Leveraging IoT and The Value of Connected Products

- The impacts of IoT on our home, work and life and what does it mean for companies that have built a reputation for creativity and innovation like 3M

- How 3M is leveraging IoT to innovate its products and solutions into the connected era as a material science based manufacturing company

- Fundamentals of and learning lessons from innovating for IoT

|

|

|

Liu Qiao

Executive Director & Chief Technical Officer

3M Japan |

|

| 16:15 |

SMEs Panel: How SMEs Can Join the Industry 4.0 Race and Start to Automate their Manufacturing Floor

- How will smart manufacturing disrupt the business models of SMEs?

- Is there a place for SMEs in smart/advanced manufacturing?

- Understanding the assistance and solutions available for SMEs

|

|

|

Koh Niak Wu

CEO

The Intelligent Warehouse |

|

|

Brandon Lee Kok Hoh

Chairman, Smart Automation Industry Group

Singapore Manufacturing Federation |

|

|

Willson Deng

Chairman

Smart Manufacturing Consortium |

|

|

Peter Toh

Senior Programme Manager

Fong’s Engineering & Manufacturing |

|

| 17:00 |

Closing Remark by Forum Chairperson |

|

|

Bob Gill

General Manager Southeast Asia

ARC Advisory Group |

|

| 17:05 |

Champagne Networking Session |

|

|

After a long day of learning, benchmarking, and planning, unwind and mingle with your peers.

|

|